When you consider the mining industry’s reliance on heavy machinery, it’s hard to overlook how gearbox manufacturers contribute to this sector’s efficiency and reliability. Their ability to innovate with smart technology and eco-friendly materials not only addresses current challenges but also shapes the future landscape of mining operations. As you explore the complexities involved, you’ll find that these manufacturers face unique hurdles that influence their designs. What are these challenges, and how do they impact the overall effectiveness of mining machinery?

Importance of Gearbox Systems

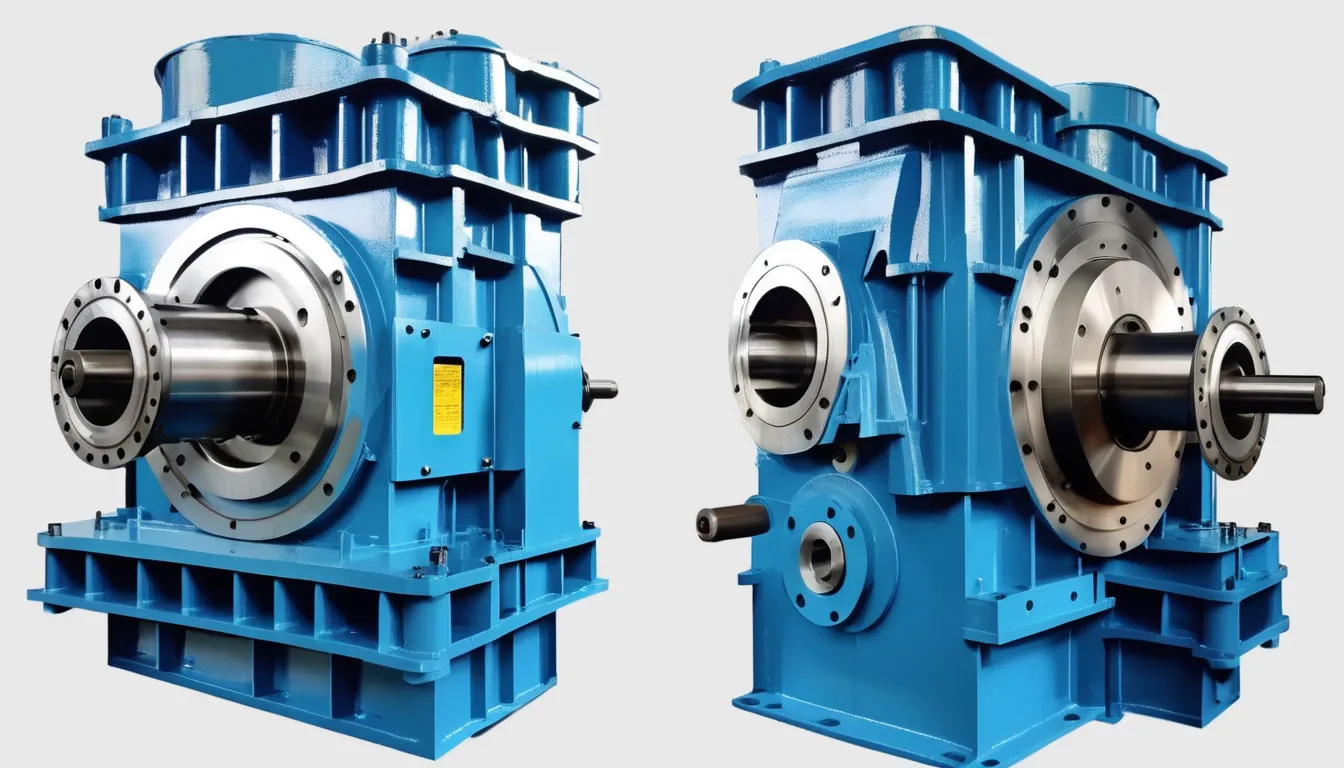

When you consider the demands of the mining industry, it’s clear that gearbox systems play a crucial role in ensuring efficient operations.

These systems are essential for converting the high-speed, low-torque output of motors into the high-torque, low-speed output required for heavy machinery. This transformation helps your equipment perform optimally, whether it’s conveyor belts, crushers, or excavators.

Gearboxes not only enhance performance but also increase reliability. They help mitigate wear and tear by distributing loads evenly across components, which reduces the risk of breakdowns.

In an industry where downtime can be costly, having a robust gearbox system means you can keep operations running smoothly.

Moreover, gearboxes contribute to energy efficiency. By optimizing power transmission, they minimize energy losses, which can lead to significant cost savings over time.

When you’re managing tight budgets and high operational demands, every bit of efficiency counts.

Key Challenges Faced by Manufacturers

Manufacturers in the mining industry face several key challenges that can impact their operations. One major issue is the fluctuating demand for mining equipment. As global markets change, you may find it difficult to predict the demand for gear systems, leading to overproduction or shortages.

Additionally, the intense competition in this sector forces you to constantly innovate while managing costs effectively.

Another challenge is the need for compliance with stringent regulations. Keeping up with environmental and safety standards can be daunting and often requires significant investment in training and technology. You may also struggle with sourcing high-quality materials, as supply chain disruptions can lead to delays and increased costs.

Moreover, the harsh operating conditions in mining environments can place significant stress on gearboxes, resulting in higher wear and tear. This means you must prioritize durability and reliability in your designs while also considering maintenance needs.

Lastly, attracting and retaining skilled labor in a specialized field is increasingly difficult. With an aging workforce, you might find it challenging to recruit young talent who possess the necessary technical skills, which can hinder your growth and innovation capabilities.

Innovations in Gearbox Technology

Recent advancements in gearbox technology are transforming the mining industry, providing you with more efficient and reliable solutions.

You’ll find that today’s gearboxes are designed with enhanced materials that withstand harsh environments, increasing their durability and longevity. Manufacturers are incorporating advanced manufacturing techniques, such as 3D printing and precision machining, to produce components with tighter tolerances, improving performance.

Another exciting innovation is the integration of smart technology. Gearboxes now come equipped with sensors that monitor parameters like temperature, vibration, and load. This real-time data allows for predictive maintenance, helping you avoid costly downtime and repairs.

You can also benefit from improved gear designs, such as helical and planetary gears, that offer higher torque capacities while minimizing noise and vibration.

Moreover, advancements in lubrication technology are making gearboxes more efficient. Synthetic oils reduce friction and wear, extending the life of your equipment.

As a result, you’re not only enhancing performance but also reducing operational costs. Overall, these innovations in gearbox technology are setting new standards in reliability and efficiency, ensuring you stay competitive in the ever-evolving mining landscape.

Impact on Mining Efficiency

The impact of advanced gearbox technology on mining efficiency is profound. When you utilize state-of-the-art gearboxes, you significantly reduce downtime and enhance the overall performance of your mining operations. These gearboxes are designed to handle high torque and heavy loads, ensuring that your machinery runs smoothly under demanding conditions.

With increased reliability, you’ll notice fewer breakdowns and interruptions, allowing your team to focus on productivity rather than repairs. Moreover, modern gearboxes often come with features that optimize energy consumption, which translates to lower operational costs. This efficiency not only boosts your profit margins but also aligns with environmental sustainability goals.

In addition, advanced china Custom gear solutions es can improve the speed and precision of your equipment. Whether you’re operating excavators, crushers, or conveyors, having the right gearbox means faster cycle times and more efficient material handling. As a result, you’re able to move larger quantities of material with reduced effort.

Ultimately, investing in high-quality gearbox technology directly enhances your mining efficiency, increases your competitive edge, and contributes to a more sustainable operation. It’s clear that the right gearboxes play a critical role in your success in the mining industry.

Future Trends in Gearbox Manufacturing

As mining efficiency continues to evolve with advanced gearbox technology, future trends in gearbox manufacturing are set to reshape the industry even further.

You’ll notice an increasing focus on automation and digitalization, with smart gearboxes that incorporate IoT capabilities. These smart devices will enhance performance monitoring, allowing for predictive maintenance and reducing downtime.

Sustainability is another key trend. Manufacturers are prioritizing eco-friendly materials and energy-efficient designs, which not only comply with regulations but also attract environmentally conscious clients.

You’ll likely see innovations that reduce the carbon footprint of mining operations.

Moreover, customization will become paramount. As the demands of the mining industry shift, you can expect gearbox manufacturers to offer tailored solutions that cater specifically to unique operational needs.

This flexibility will lead to improved efficiency and performance.

Conclusion

In conclusion, gearbox manufacturers are vital to the mining industry, driving efficiency and innovation. By addressing challenges and embracing new technologies, they enhance machinery performance and support sustainability efforts. As the industry evolves, staying ahead of trends will be crucial for these manufacturers to maintain competitiveness. Ultimately, their contributions not only boost productivity but also ensure that mining operations can meet the demands of a more eco-conscious world.